A laboratory centrifuge is one of the most essential tools in modern laboratories, playing a critical role in research, diagnostics, and industrial applications. Whether in clinical laboratories, research institutions, or industrial plants, centrifuge machines are indispensable for separating components of a mixture based on their density and mass.

Understanding how a centrifuge works, its applications, and how to select the best model for your needs is crucial for maximizing efficiency and achieving precise, consistent results. This guide will take you through the fundamentals of centrifugation, explore different types of centrifuges, and provide expert insights into their operation and maintenance.

If you're looking to buy a laboratory centrifuge in Afghanistan, Denagene Tajhiz offers a high-speed centrifuge (15,000 RPM) designed for clinical, pharmaceutical, and research applications. Explore our best centrifuge models for accurate and efficient sample separation.

A centrifuge machine is a powerful laboratory device that separates mixtures based on density differences using centrifugal force. By spinning a sample at high speeds, it accelerates the natural sedimentation process, allowing for the rapid and efficient separation of components that would otherwise take much longer under normal gravity.

At its core, a centrifuge machine consists of a motor-driven rotor that holds sample tubes. As the rotor spins, it generates centrifugal force, pushing denser particles outward toward the bottom or sides of the tubes while lighter particles remain suspended or rise to the top.

The speed of a centrifuge is measured in Revolutions Per Minute (RPM) or Relative Centrifugal Force (RCF), also known as g-force. While RPM determines the speed of rotation, RCF measures the actual force applied to the sample, making it the key factor in achieving proper separation.

Centrifuges play an essential role in various scientific and medical fields, including:

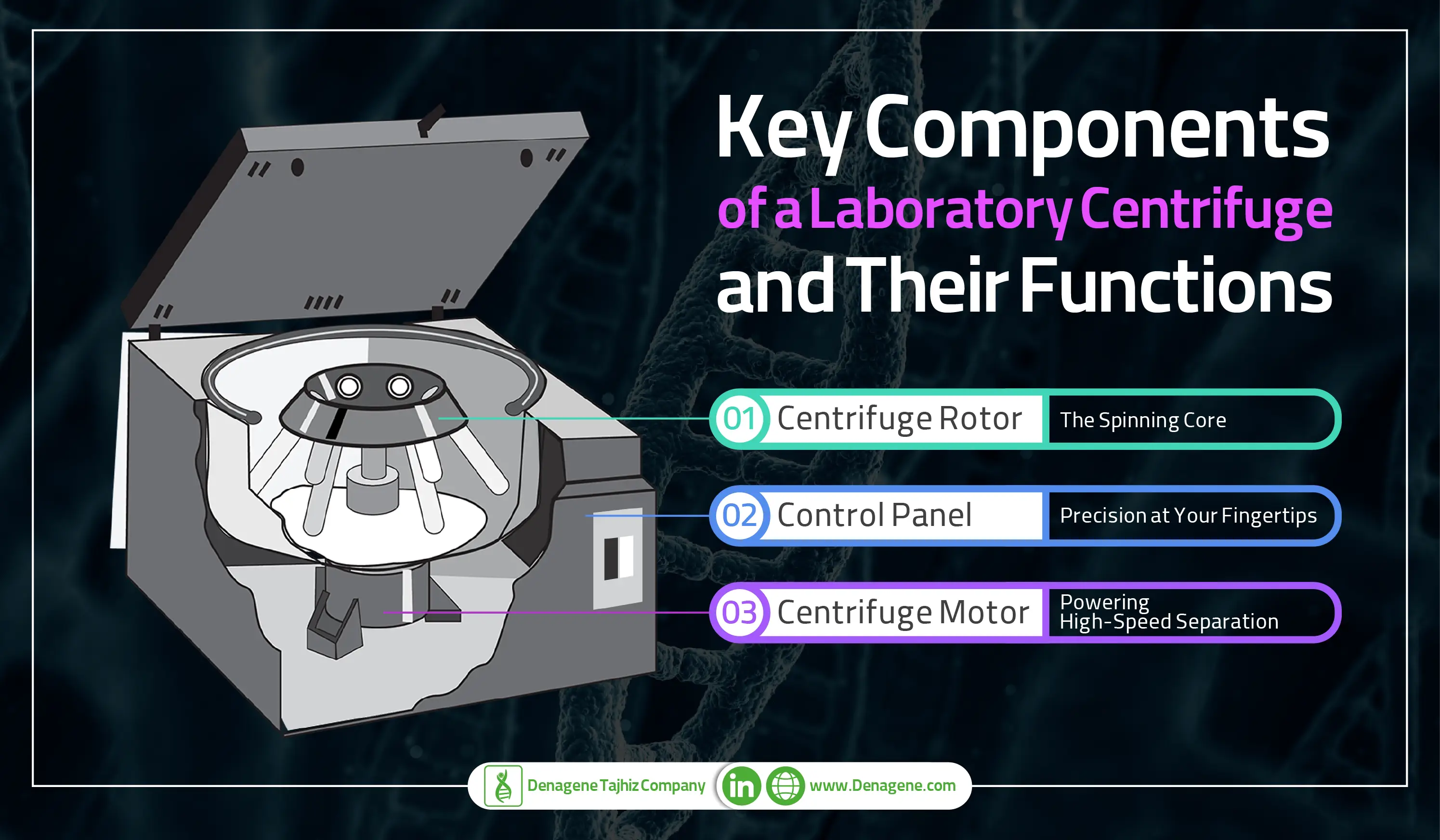

A centrifuge machine is composed of several critical components, each contributing to its overall functionality and efficiency. Understanding these key elements can help laboratories choose the right centrifuge based on their specific research and diagnostic needs.

The rotor is the central component of a laboratory centrifuge, responsible for holding sample tubes and generating the centrifugal force needed to separate components based on their density.

There are two primary types of rotors:

The rotor speed is a crucial factor in achieving accurate sample separation, particularly in high-speed centrifuges (15,000 RPM+), which are widely used in medical and research laboratories in Afghanistan.

The motor is the heart of any centrifuge machine, driving the rotor to achieve the necessary speeds for sample processing.

A high-quality centrifuge motor ensures reliable and precise operation, which is vital for temperature-sensitive samples in clinical and pharmaceutical settings.

The control panel of a modern laboratory centrifuge allows users to customize and monitor settings, ensuring precision and repeatability in experiments.

A centrifuge machine is an essential tool in research, clinical, and industrial laboratories. However, improper use can lead to equipment damage or serious injuries. Following proper centrifuge safety protocols ensures efficient operation, protects users, and extends the lifespan of the machine.

For laboratories in Afghanistan looking for the best centrifuge machines, Denagene Tajhiz provides top-quality centrifuges designed for clinical, research, and industrial use.

Looking for the best centrifuge machine price in Afghanistan? Contact us today for details on high-speed centrifuge models.